About Department

| COURSE NAME | DE (MECHANICAL) |

| YEAR OF STARTING | 2013 |

| INTAKE | 60 |

| COURSE DURATION | 3 YEARS |

| NO. OF LABORATIES | 19 |

INTRODUCTION OF DEPARTMENT

Pacific School of Engineering (Diploma), Surat was established in 2013 and the Mechanical Engineering Department is part of the institute since its inception. The mechanical engineering department is running Diploma engineering course since 2013 having the current intake of 60 seats. Mechanical engineering is a discipline of engineering that applies the principles of physics and materials science for analysis, design, manufacturing, and maintenance of mechanical systems. It is the branch of engineering that involves the production and usage of heat and mechanical power for the design, production, and operation of machines and tools. It is one of the oldest and broadest engineering disciplines.The engineering field requires an understanding of core concepts including mechanics, kinematics, thermodynamics, and materials science. Mechanical engineers use these core principles along with tools like computer-aided engineering and product lifecycle management to design and analyze manufacturing plants, industrial equipment and machinery, heating and cooling systems, transport systems, aircraft, watercraft, robotics, medical devices and more.Mechanical engineering emerged as a field during the industrial revolution in Europe in the 18th century; however, its development can be traced back several thousand years around the world. Mechanical engineering science emerged in the 19th century as a result of developments in the field of physics. The field has continually evolved to incorporate advancements in technology and mechanical engineers today are pursuing developments in such fields as composites, mechatronics, and nanotechnology.

VISION

To create the positive environment for quality based education in the field of Mechanical Engineering for preparing socially responsible technocrats and entrepreneurs , who pursuing advanced studies through synergized coursework, practical knowledge, and cutting-edge co-curricular activities to play a vital role in the development of the nation.

MISSION

- To undertake industry-related projects which offer real-time opportunities to analyze and understand problems

- To create facilities for education and training through continued interaction with industries.

- To make our graduates fundamentally sound by imparting quality classroom teaching and practical learning in laboratories

- To nurture the talent of students by various co-curricular activities for preparing job-ready engineers and competent entrepreneurs in the development

of the nation. - To provide the necessary guidance to the students wanted to pursue higher education

PROGRAM SPECIFIC OUTCOMES (POs)

Engineering Knowledge: Able to apply knowledge of basic sciences (maths, physics, chemistry, etc.) and engineering (core and elective subjects)

in getting solutions to mechanical engineering related problems

Fundamentals: Understand the fundamental terminologies, and able to brief the engineering principles, concepts, and phenomenons.

Problem Analysis: Identity, formulate and analyze complex engineering problems and reaching the conclusions

Design/ Development: Design various components with CAD software that meet specific needs of development with appropriate considerations

Individual and Team Work: Demonstrate knowledge and understanding of Production and Industrial Engineering and management principles

and apply these during project work, as a team member and leader in a team, to manage projects

Nation and Society: Apply contextual knowledge and skill to function effectively in various activities to assess environmental, societal, health, safety, legal and cultural issues, and the consequent responsibilities

Life-long learning: Ability to analyse individual needs and engage in updating in the context of technological changes.

PROGRAM EDUCATIONAL OBJECTIVES (PEOs)

PEO1: Graduates will be employable and apply the knowledge of Mechanical Engineering to solving real-world Engineering problems.

PEO2: Graduates will have leadership skills for becoming techno-entrepreneur.

PEO3: Graduates will have the required attributes to pursue advanced education in Engineering and Technology.

PROGRAM SPECIFIC OUTCOMES (PSOs)

PSO1 Our graduate engineers will apply all the basic principles of mechanical engineering required in industries.

PSO2 We produce graduate engineers specialized in Computer-Aided Design, Thermal and Manufacturing.

PSO3 Our students are well equipped with knowledge of industrial engineering and quality management.

PSO4 Our graduate will be able to participate in various competitive examinations.

Head of Department Desk

Welcome to the Department of Diploma Mechanical Engineering at Pacific School of Engineering, Surat. The aim of department of Mechanical Engineering is to disseminate knowledge and technologies through quality teaching and its applications in mechanical disciplines. In our creative and attractive curriculum, we strive to assimilate the latest developments in mechanics, dynamics, thermo-fluid, energy, and manufacturing.

We strive to ensure that all our young students have a strong education with leadership, management and teaming skills, internship experience, and involvement in student activities. We entrust that accentuating these areas will make our young students well-qualified to take leadership roles in the future.

Prof. Vipul Moradiya

Head, Mechanical Engineering Department

Faculty Members

Name : Dr. Kandarp M. Joshi

Designation : Vice Principal

Qualification : Ph.D (Maintenance Management), M.Tech (Mechanical), B.E.

Experiance : 17 Years

Email Id : j.kandarp.pse@gmail.com

Name : Prof. Naitik Patel

Designation : Head of Department

Qualification : M.Tech (THERMAL), B.E.

Experiance : 5 Years

Email Id : naitupatel220@gmail.com

Name : Prof. Vipul Moradiya

Designation : Assistant Professor

Qualification : M.Tech. (Industrial Engineering), B.E.

Experiance : 16 Years

Email Id : vip21mvh@gmail.com

Name : Prof. Chaitanya Madrasi

Designation : Lecturer

Qualification : M.E. (Production), B.E.

Experiance : 6 Years

Email Id : royalmechanical.cvmadrasi@gmail.com

Name : Prof. Dhruval Patel

Designation : Lecturer

Qualification : B.E (Mechanical)

Experiance : 4.5 Years

Email Id : pse.dhruval@gmail.com

Name : Prof. Dhruv Patel

Designation : Lecturer

Qualification : M.E (Machine Design), B.E.

Experiance : 3 Years

Email Id : dhruvspatel2015@gmail.com

Name : Prof. Ajay Kalsariya

Designation : Lecturer

Qualification : B.E.

Experiance : 3.5 Years

Email Id : kalsariyaajay0203@gmail.com

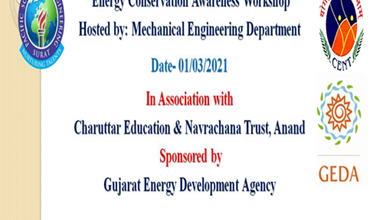

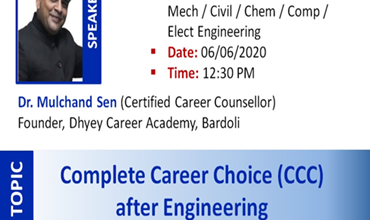

Expert lecture / Seminar / Workshop

Audians:: All Engineering Students

- To introduce the basic concept of about energy conservation.

- To bring about the awareness amongst the participants to save and conserve energy.

- To discuss different means and applications related to energy conservation.

- To interact with participants through different sessions of industry experts to demonstrate the practical oriented approach about energy conservation.

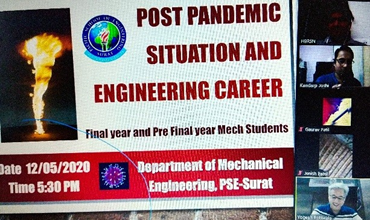

Audians:: Final Year Students of Mechanical Engineering Department

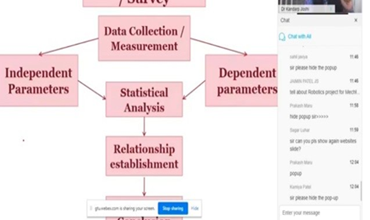

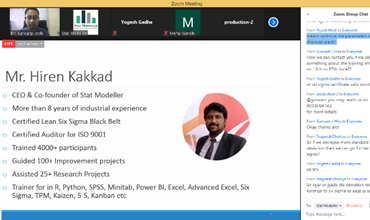

Audians:: All the students of Mechanical Engineering Department

Audians:: 3rd Year students of Mechanical Engineering Department

Audians:: All Engineering Students

Audians:: All the students of Mechanical Engineering Department

Topics Covered By Different Faculty Members:

Dr. Kandarp Joshi - Industry 4.0

Prof. Bharat Khalasi - opportunities for Mech in Non-core Field

Prof. Vatsal Patel - E commerce and Health care

Prof. Jasmin Hirpara - Industrial Safety & Job Opportunity

Prof. Dharmesh Babariya - GATE and Government Job.

Prof. Hiren Patel - Industrial Aspects of Design Field.

Audians:: Final year students of Department of Mechanical

Point to be covered:

- Two mechanical equipment (Pumps And Compressors) with deep technical presentation. (Mechanical Equipment Operation, Codes, Standards and Specification, etc)

- Roll of Mechanical Engineers in Industries.

- Type of Industries available in the world.

- How Industries run

- Organization Structure of the industry.

- Departments available in Industries

Audians:: Final year students of Department of Mechanical

ESPIRIT is a powerful full-spectrum CAM system for CNC programming and simulation, supporting the manufacturing process from CAD files to machined part. With factory-certified post processors delivering machine-optimized G-code, ESPRIT is the smart manufacturing solution for any machining application. ESPRIT is a comprehensive CAM solution specifically designed to meet the demands of production machining. ESPRIT includes advanced support for: 2-5 axis mills 2-22 axis lathes multifunction lathes and mill-turn machines 2-5 axis wire-EDM. ESPRIT and SOLIDWORKS both utilize the Para solid modelling kernel. This means direct exchange of design models from SOLIDWORKS into ESPRIT, eliminating translation. Within ESPRIT, all machining is performed directly on the solid model as designed, assuring integrity of the final part. ESPRIT's adaptive connection to SOLIDWORKS means any changes in the SOLIDWORKS model are reflected inside ESPRIT and the G-code program. ESPRIT's Solid Simulation and Verification dry runs part programs on the computer to verify accuracy before actual machining. View designs on screen within the entire machining environment, including fixtures, clamps, and stock material. Everything is clearly rendered in dynamic 3D solid images. ESPRIT then accurately simulates every machine movement ensuring accurate G-code.

Audians:: ALL THE MECHANICAL STUDENTS

Audians:: ALL THE MECHANICAL STUDENTS

Audians:: 2nd, 4th and 6th Sem Mechanical Students

Audians:: 4th and 6th Sem Mechanical Students

Our Departmental organizing committee arrange one day Expert Lecture on "Thermodynamics and Fundamental of Refrigeration". Our Expert lecturer gives basic knowledge related to thermodynamics and its cycles. also give the information regarding the Refrigeration knowledge and its working Principle.

Industrial Visits

Rajdeep Boiler Pvt. Ltd. (RBPL) is one of India's premier engineering organizations, with a humble beginning in 1999 and has gradually grown to be a major player in providing steam generation solutions for process and power needs.

RBPL is a leading resource for design, innovation, manufacture and commissioning of boilers and auxiliaries, with decades of experience in serving diverse industries. RBPL has the necessary presence, competence and solutions to provide a broad range of technologies across major industries.RBPL are fully equipped with Ultra Modern Machineries required to produce highest quality product. All the major activities such as Shell Rolling, Drilling Tube Bending, all types of Welding Processes, NDE's and Hydro Tests is carried out in-house, to produce good quality products and meet time-bound deliveries.Whatever be your field of industry, RBPL can help you meet your energy demands with improved cost efficiencies. RBPL can also efficiently partner you for waste heat recovery, incinerators for hazardous waste and a wide array of air pollution control equipment.

A visit of Sumul Milk producer union . Ltd., Surat is arranged on 10/01/2020. 30 students of 6th sem (Third year) and 3rd SEM (second year) Mechanical Engineering Department visit the Company in two Batches.

Sumul or Surat Milk Union Limited, which is now renamed as The Surat District Co-operative Milk Producers' Union Ltd, is one among the 17 district unions which acts as manufacturing units of dairy products for Gujarat Co-operative Milk Marketing Federation Limited, the marketers of Amul brand of products.

A visit of DOMS Industries pvt. Ltd., Umargam is arranged on 28/09/2019. 30 students of 5th SEM (Third year) and 3rd SEM (second year) Mechanical Engineering Department visit the Company in two Batches.

DOMS INDUSTRIES PRIVATE LIMITED is a private incorporated on 24 October 2006. The Company is Specially Engaged in Manufacturing of Color Pencil, df pen, Pencil Eraser , pencil Sharpener , Plastic Scale , Wax Crayons , Wooden Pencil. This Company is a Best Stationary Product Company in Gujarat.

The department of Mechanical Engineering, Pacific School of Engineering Organized an Industrial visit to Indo-German Tool Room on 29th of August 2019 For B.E Mechanical Engineering students.

The visit was organized with the prior permission and guidance of Principal Dr. Jayesh Shah and HOD of Mechanical Department Mr. Vipul Moradiya.

The students of third year and Second year Mechanical and the Four staff members have enjoyed the technical endeavor at the organizations a lot. Visit seems to be very informative and gives good learning experience. It was the unique example of ‘EDUTAINMENT’ i.e.Education & Entertainment.

A visit of Nuclear Power Corporation of India Ltd., Kakrapar is arranged on 07/07/2018. Final year student of Mechanical Engineering Department visit the NPCIL with four faculty members.

Batliboi Limited was established in the year 1892, the company is a part of Batliboi Group, which focuses on wind energy, environmental engineering, motors, international marketing and logistics.The Batliboi Group is divided into four main divisions, which are machine tools, special purpose machines, crane foundry and remanufacturing and reconditioning center.

A visit of BATLIBOI LTD at Surat is arranged on 09/09/2017. 28 students of 3 year Mechanical Engineering Department along with 2 faculty members.

We visited this plant for getting the knowledge about actual working of different types of components which are related to mechanical engineering.

The most attractive and knowledgeable think for us is to actual working of CRDI in automobile and try to better understand about actual difference between ID, DI, CRDI Systems works in automobiles.

We thanked for company to give us the permission for visit their extremely work.

A visit of Sewage Treatment Plant at Anjana , Surat is arranged on 06/03/2017. 15 students of 3rd year of Mechanical Department along with 2 faculty members.

A visit of Sardar Sarovar Nigam Ltd. is arranged on 30/01/2017. 20 students of 3rd year, 15 students 2nd year and 09 students of 1st year of Mechanical Department along with 3 faculty members and 1 Lab assistant.

A visit of Chalthan Sugar Factory at Chalthan is arranged on 02/07/2016. 18 students of final year, 19 students of 3rd sem and 20 students 1st sem Mechanical Department along with 4 faculty members and 1 lab attendants have visited the factory in two batches.

J.K. Paper Ltd. has two large integrated Paper Manufacturing units – JK Paper Mills, Rayagada, Odisha and Central Pulp Mills, Songadh, Gujarat with a combined capacity of 4,55,000 TPA. It is the market leader in Branded Copier paper segment and among the top two players in Coated Paper and high-end Packaging Board.

Its products are sold through extensive distribution network of 188 wholesalers, 10 depots & 4 regional marketing offices, and covering nearly 4,000 dealers. It offers a wide product range and its brands are synonymous with premium quality paper.

A visit of J.K.Paper Ltd. at Songadh is arranged on 19/03/2016. 23 students of 3 year Mechanical Engineering Department along with 2 faculty members.

The Industrial visit was organized for 3rd and 5th sem Mechanical Students, For creating awareness and provide guidance regarding Practical Knowledge Power Plant and fluid engineering.

The Ukai Dam, constructed across the Tapti River, is the largest reservoir in Gujarat. It is also known as Vallabh Sagar. Constructed in 1972, the dam is meant for irrigation, power generation and flood control. Its earth dam is 80.77 meters high, whereas the masonry dam is 68.68 meters high.

A visit of Gujarat State Electricity Corporation Limited at Ukai is arranged on 28/09/2015. 22 students of 3rd sem and 28 students of 5th sem of Mechanical Engineering Department along with 4 faculty members.

Batliboi Limited was established in the year 1892, the company is a part of Batliboi Group, which focuses on wind energy, environmental engineering, motors, international marketing and logistics.The Batliboi Group is divided into four main divisions, which are machine tools, special purpose machines, crane foundry and remanufacturing and reconditioning center.

A visit of BATLIBOI LTD at Surat is arranged on 22/09/2015. 30 students of 3 year Mechanical Engineering Department along with 2 faculty members.

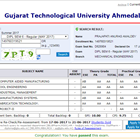

Student Achievements

Laboratories

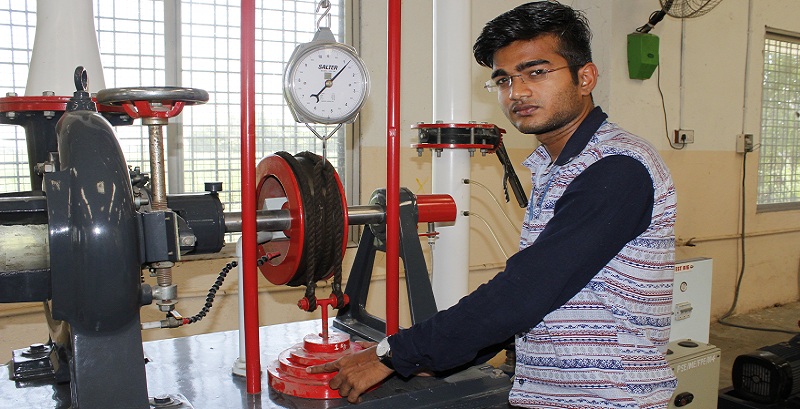

Fluid Mechanics Lab

|

Lab Name |

Fluid Mechanics |

|

Lab Description |

FM lab is well equipped with the different setups. In this lab the behavior of fluids can be learn like flow measurement, velocity of fluid. This lab is used in third semester in Mechanical Engineering. |

|

Configuration |

3-Phase Power supply |

|

No. of Machines |

13 |

Basic of Mechanical Engineering Lab

|

Lab Name |

Basic of Mechanical Engineering |

|

Lab Description |

It’s a basic mechanical lab in which basic knowledge of mechanical is given. This lab is used in first year of engineering. The models are available to study like boilers, gears, brakes, pumps, clutches etc. |

|

Machines Details |

Babcock Boiler Model, Cochran Boiler Model, Lancashire Boiler Model, 4-S petrol & 4-S diesel engine Model, Different types of Gears |

Theory of Machine Lab

|

Lab Name |

Theory of Machines |

|

Lab Description |

TOM Lab is well equipped with all the experimental setups required as per GTU syllabus. TOM Lab used in second year of Mechanical Engineering |

|

Configuration |

Power Supply (Single Phase) |

|

No. of Machines |

04 |

Manufacturing Process Lab

|

Lab Name |

Manufacturing Process |

|

Lab Description |

MP lab is well equipped with the high grade machines like lathe, milling, universal drill, shaper machine, power hacksaw, etc. this lab is used in second and third year of Mechanical Engineering. |

|

Configuration |

3-Phase power supply |

|

No. of Machines |

20 Machines |

I.C. Engine Lab

|

Lab Name |

Internal Combustion Engines |

|

Lab Description |

IC Engine Lab is well equipped with all the experimental setups required as per GTU syllabus. IC Engine Lab used in second and third year Mechanical Engineering. |

|

No. of Machines |

08 |

Material Science and Metallurgy Lab

|

Lab Name |

Material Science & Metallurgy |

|

Lab Description |

MSMT lab is equipped with good equipment. This lab is used in second semester of Mechanical Engineering. |

|

Machine Details |

Muffle Furnace, Double Disc Polishing Machine, Metrological microscope, binocular Metallurgical Microscope, Rockwell Hardness Tester |

Computer Lab

|

Lab Name |

CAD / CAM |

|

Lab Description |

CAD/CAM lab is well setup by the necessary software. This lab is used in second year of Mechanical Engineering. |

|

Configuration |

Power Supply, UPS |

|

No. of Machines |

28 (computers) |

Workshop

|

Lab Name |

Workshop |

|

Lab Description |

Workshop is heart of Mechanical Engineering. Workshop is used in first year Engineering. In this lab the basic mechanical processes can be learn like carpentry, fittings, tin smithy etc. |

|

Machine Details |

Power Hacksaw, Drilling Machine, Grinding machine, Furnace, 6 Tables with vices |

Metrology and Instrumentation

|

Lab Name |

Metrology & Instrumentation |

|

Lab Description |

M & I lab is equipped with good equipment. This lab is used in fourth semester of Mechanical Engineering. |

|

Configuration |

Power Supply (Single Phase) |